Manifold Design

This document tries to explain the basic elements of a properly designed exhaust manifold for XK engines and the benefits a well-designed system can bring. There are various designs of manifolds available and you may be driven by budget, but in all cases the customer should have some basic understanding of what they are getting for their money.

There is a lot more information and detail available around the performance of different lengths and diameters of primary pipes * and the effect of them on different levels of engine upgrades eg larger valves, H.C. pistons camshafts etc but what I have tried to do is enlighten the owners of cars fitted with an XK engine to the basics of tubular manifolds if they are considering changing from the standard ‘Cast Manifold’ on a standard engine.

The short video of Classicfabs Manifolds show the benefit and necessity of a properly designed ‘merge’ collector along with all the other elements of a well designed Manifold.

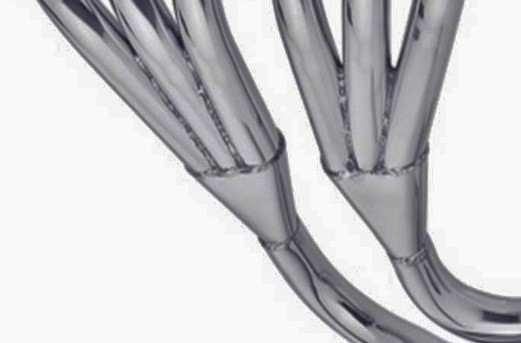

A ‘one piece’ merge collector compliments the design and performance of the complete tubular manifold

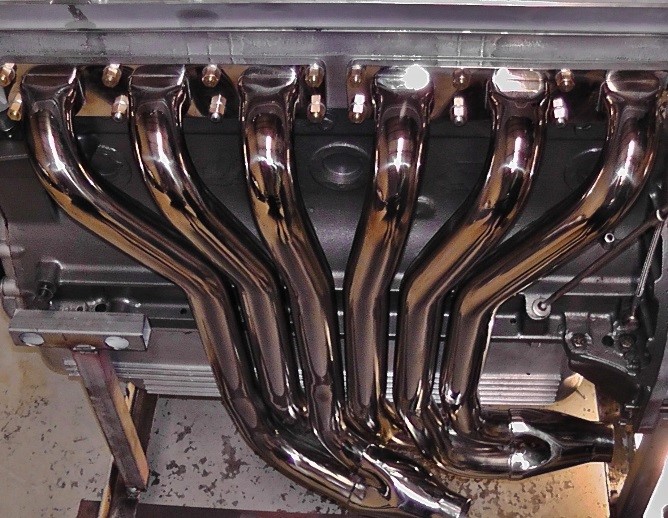

The inlets at the exhaust flange ports where using the internal flange weld by Classicfabs created by using specially designed tooling gives the smoothest transition from the rectangular exhaust ports to circular along with the smooth mandrel bent tubing helping to give the maximum flow characteristics throughout the primary pipe lengths and as the interface of the three pipes at the collector are combined to be parallel to each other this gives a ‘laminar flow’: ie the gasses flow in the same direction as they combine at the merge collector. This creates a much better scavenging effect on each adjoining port by helping pull the exhaust gasses from the adjacent exhaust ports.

There are other less expensive ways of combining manifold primary pipes for XK engines that are used but these potentially will be not as efficient as a properly designed ‘merge collector. (See Note)

Even with the Classicfabs 41” long primary pipe system the collector still creates a vacuum at each of its adjacent ports.

Our Standard Long and Short Manifold videos also show the benefit of a properly designed Primary pipe and merge collector system

Any good design of Tubular / Performance header needs the additional benefits of a well-designed primary pipe merge collector system.

Note : These other primary pipe joining procedures are where the three pipes from cylinders 123 or 456 are either ‘slotted’ and welded together or a piece of stainless sheet has been wrapped around the interface of the three primary pipes and welded to create the collection system.

Summary:

In tubular manifolds as in any other part you are purchasing for your car:

What do I expect from a tubular manifold?

Is budget a consideration?

What am I getting for my money with regard to performance, if you are buying a Tubular Manifold you should expect some sort of performance enhancement.

As well as the longevity of stainless will the manifold design enhance the performance of the engine?

Does the manufacturer provide evidence of any performance benefit.

How did the manufacturer arrive at the length of the Primary pipes before the collection system and what do they expect the enhanced performance to be.

What is the interface of the pipes like in the inside eg. Has it been fully purged while welding, do the primary pipes join together accurately inside giving it the best possible flow for its specific design.

Have they thought about the aesthetics of the design of the primary pipes prior to the collection system? If the manifold is made from basically three pipes bent at ninety degrees with short primary pipes to collector or interface then this design potentially will not to be as efficient or expensive as one where the primary pipes have been formed to end up parallel to each other.

*Primary pipe is the description given to exhaust pipe where it leaves the exhaust flange to where it converges with the other exhaust pipes at the collector / interface.

Below are two types of tubular manifolds available for various XK engines showing the interface / collection system. Do they assist in scavenging.

Below are two variations of Classicfabs tubular manifolds for E-Type’s showing well designed primary pipes leading to a merge collector creating parallel flow which assists with adjacent exhaust port scavenging